For some US manufacturers, tariffs signal potential growth opportunities

Published in Business News

BALTIMORE — Factory owner Ken Malone has already experienced the ups and downs of tariffs launched this month. But, in President Donald Trump’s trade strategy, he also sees an opportunity to grow his business.

At Early Charm, Malone and his 40 employees transform scientific discoveries into materials, such as 3D-printed plastic, electronic components and ceramic and biological parts.

The business, which opened a Southwest Baltimore facility nearly two years ago, has seen less demand for sonar systems it makes for shrimp farmers around the world. That’s because farmers in Ecuador, for instance, now have less demand in the U.S. for higher-tariffed shrimp.

But the factory also makes parts for hydrogen fuel cells and other industrial products. Possible new customers have been looking for U.S.-based alternatives to Chinese suppliers because of the new tariffs. The potentially hundreds of thousands of dollars that could flow in over the next few months could balloon to tens of millions of dollars long term and lead to more high-paying production jobs, Malone said.

“That’s what we’re really looking toward,” Malone said. “These are the jobs that are transformative and create equitable economic development. The young people who come into our manufacturing operations at those levels then get to work with our engineers and scientists and see a world of opportunity.”

Some Maryland manufacturers, like Malone, welcome Trump’s tariff strategy as long overdue. They argue the state must seize a chance to rebuild its manufacturing economy and attract high-paying jobs that will elevate more people to the middle class.

Since Trump announced multi-country tariffs at the start of April, then subsequently paused some, stock markets have traveled a roller coaster of ups and downs, and consumers and small business owners have braced for price hikes on imported products, parts and raw materials. The tariffs, which are taxes on products imported from other countries with costs often passed on to consumers, are part of Trump’s strategy to protect U.S. industry from unfair foreign competition.

Supply chain experts and economists have criticized broad-based tariffs as harmful to consumers and the economy, with prices expected to rise on apparel, mobile phones, furniture, cars and imported food. Some say the policies are unlikely to fix the U.S. trade deficit or rebuild employment in manufacturing because exports will be reduced along with imports. And large investments would be needed both from producers and the government for the strategy to succeed, experts say.

But Drew Greenblatt, owner of a West Baltimore-based maker of steel wire baskets and products for the aerospace, defense, medical and automotive industries, calls the tariffs “fabulous news.”

His 115-employee company, Marlin Steel Wire, buys steel from U.S. producers, runs factories in Indiana and Michigan and exports to 40 countries, though most sales are in the U.S.

“American manufacturing is getting an opportunity to thrive and grow,” Greenblatt said. “The reindustrialization of America is going to happen. The wildly unfair deals, by both Democrats and Republicans, have been very harmful to the American workers.”

Such policies have led to decades of domestic manufacturing job losses and especially devastating to neighborhoods in Baltimore such as Sandtown-Winchester, where Marlin Steel runs a production plant, and in other neighborhoods where factory workers once lived in now vacant rowhouses, Greenblatt said.

In its Baltimore plant, Marlin Steel makes an expanded metal basket that is hit with a $129 tariff when exported to Germany, putting the product out of reach for much of that market, he said.

Unfair competition in other countries means Marlin Steel “can’t hire a guy or gal from Sandtown. In Germany, England and China we have similar kinds of outrageous disadvantages for the American worker. If you support American workers, you support a fair, level playing field with tariffs.”

Greenblatt agrees that rising consumer prices will be painful in the short run.

“This is a reset,” he said. “Some companies are going to see cost increases, and you and I are going to pay more for T-shirts, but it’s more important for me to have $80,000 to $100,000-a-year factory jobs,” with benefits and advancement opportunities.

At a time when federal government jobs are unlikely to return, Greenblatt said he is hopeful state and city officials will actively recruit and support manufacturers and compete for them with other states.

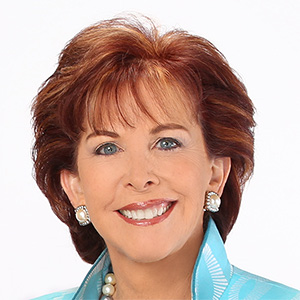

Greenblatt hosted a U.S. Small Business Administration official and a media tour of his Merchant Drive facility on Friday. The visit by administrator Kelly Loeffler was planned to underscore how restoring American industry will “create good-paying jobs, secure our supply chains, and unleash new growth and opportunity across our communities,” the SBA said.

To what extent any of that occurs will depend in part on individual companies’ ability to expand. Some might be able to easily increase production capacity to meet a market demand driven by more expensive Chinese imports. Others might not, said Darius Irani, chief economist for the Regional Economic Studies Institute at Towson University.

“To change the course of manufacturing requires a substantial amount of capital investment by these companies,” Irani said. The uncertainty clouding each new tariff announcement “may not be an environment in which a business wants to invest millions if not billions of dollars upgrading their supply chain, upgrading their manufacturing facilities, to have an increase.

“They might find that they’ve done all that work, only to find that the tariffs have been paused or not implemented,” he said.

As proposed, the tariffs are a mixed bag, said Kenneth Sanchez, president of Baltimore-based Chesapeake Specialty Products, which makes products such as foundry sand additives, metallic abrasives and high-density materials used in the foundry industry, commercial painting and industrial sectors.

He said U.S.-based manufacturers struggle to compete internationally when countries tax imports and also impose value-added taxes, or VATs.

Such levies at various stages of production and distribution “often drive up our prices compared to local products,” he said in an email to The Baltimore Sun.

“Though last week’s tariff announcements sparked chaos and concern, we’d welcome them if they spark negotiations that ease access for U.S. goods into foreign markets,” Sanchez said. “Ideally, we’d love a world with no U.S. tariffs, no foreign tariffs, and no VATs — free-flowing commerce lifts every economy.”

He said inflation has driven up the costs of parts and materials for his company’s factory, and new tariffs could push those costs higher. The 10% baseline tariffs and potential cost hikes from reciprocal tariffs, such as 125% on China, could raise costs and squeeze margins at the Baltimore plant.

But if the Trump administration’s moves pressure other countries to lower value-added taxes and other import barriers, exports, which make up 40% of sales, could see a boost. Lowering barriers in Brazil could slash prices by 35% for customers, for instance, he said.

Chesapeake Specialty’s production takes place mostly in Baltimore, with some in South Korea. About 40% of sales come from international markets.

“If these tariffs lead to lower overseas barriers, our export business could grow much faster — we’re eager to see how it unfolds,” he said.

©2025 The Baltimore Sun. Visit at baltimoresun.com. Distributed by Tribune Content Agency, LLC.

Comments